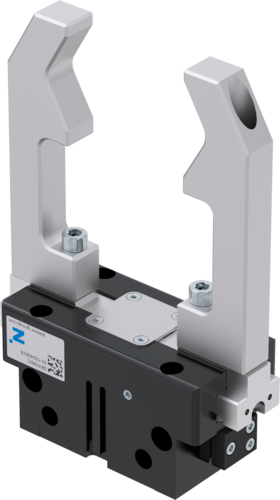

2-Jaw Parallel Grippers

Series GP400

"The economical"

- Concentration on the essentials

The most economic type of gripping: This is how you reduce your production costs - Proven T slot guide

This established and proven guiding technology stands for the highest process reliability like no other - Compact structure

Reduces the interference contours for your application

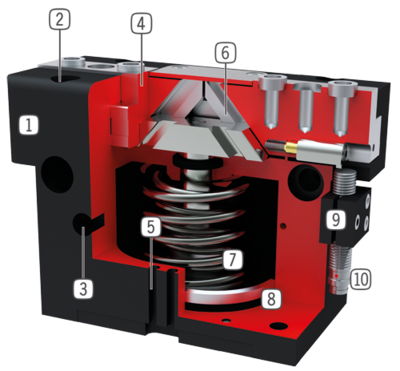

Series features

10 million maintenance-free cycles (max.)

10 million maintenance-free cycles (max.) Spring closing C

Spring closing C Spring opening O

Spring opening O High-strength S

High-strength S IP40

IP40 Magnetic field sensor

Magnetic field sensor Inductive sensor

Inductive sensor Purged air

Purged air

- Robust, lightweight housing

Hard-coated aluminum alloy - Mounting and positioning

mounting possible from several sides for versatile positioning - Energy supply

possible from several sides - Gripper jaw

individual gripper finger mounting - Sensing slot

mounting and positioning of magnetic field sensors - Wedge hook mechanism

synchronized the movement of the gripper jaws - Integrated gripping force safety device

spring integrated into cylinder as energy storage - Position sensing

permanent magnet for direct monitoring of piston movement - Mounting block

mounting for inductive proximity switch (10)