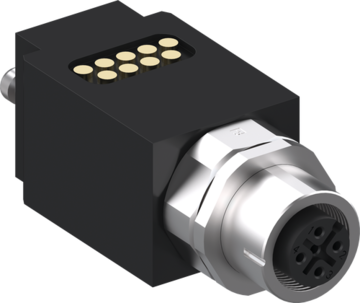

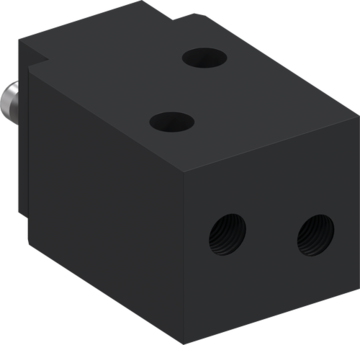

HWR2050L

Tool Changers

Series HWR2000

- Change in seconds

Reduce your start up costs and minimise downtimes by changing your tool in seconds - Integrated air transfer system

For supplying pneumatic actuators. Additional media can be transmitted using optional energy elements. - Includes loss protection

Undesired falling of work pieces is eliminated - this means the highest safety for man and machine

Technical Data

| Connecting flange according EN ISO 9409-1 | TK 50 |

| Type of drive | manual |

| Pneumatic energy transfer | 8 [Quantity] |

| Electrical energy transfer | optional |

| Flow per connector | 150 [l/min] |

| Self locking mechanism when locking | mechanical |

| Repetition accuracy in Z | 0.01 [mm] |

| Repetition accuracy in X, Y | 0,02 [mm] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | 5 ... +80 [°C] |

| Moment of inertia | 0.67 [kgcm²] |

| Approvals | LABS / REACH / RoHS |

| Weight | 0.11 [kg] |

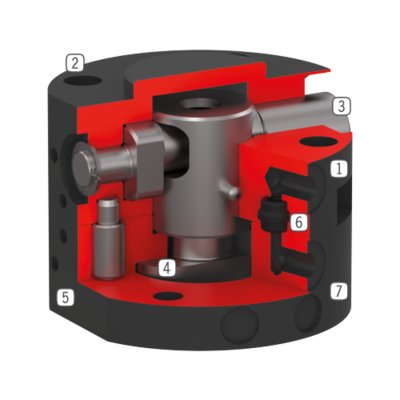

Benefits in detail

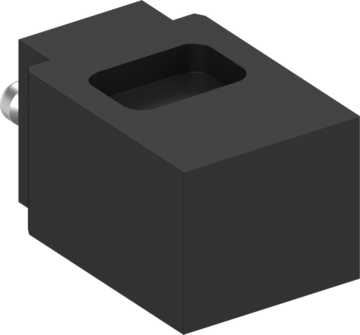

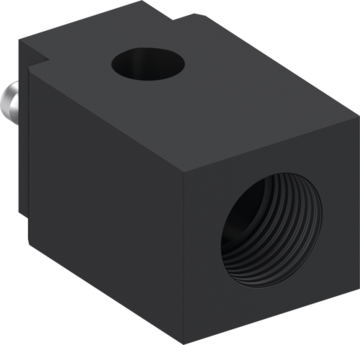

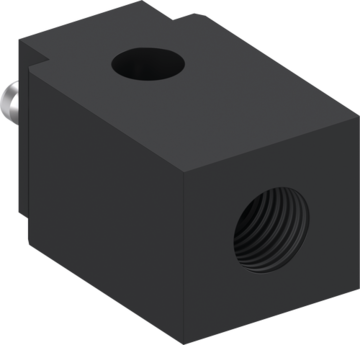

- Fix part

For robot side assembly - Robot flange

partial mounting circle in accordance with EN ISO 9409-1 - Eccentric locking bolt

with spring supported snap in function - Locking bolt

adapted to the clamping sleeve - Mounting for energy element

- Integrated air feed-through

Air / vaccum transfer Hoseless control possible - Loose part

For tool side assembly

Energy Elements

Transmission mode Communication

Transmission mode Protective element

Transmission mode electrical