Efficient all-rounder

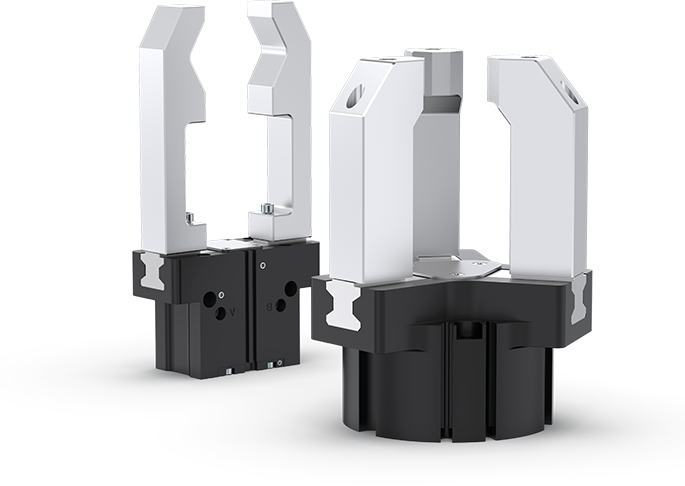

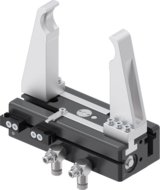

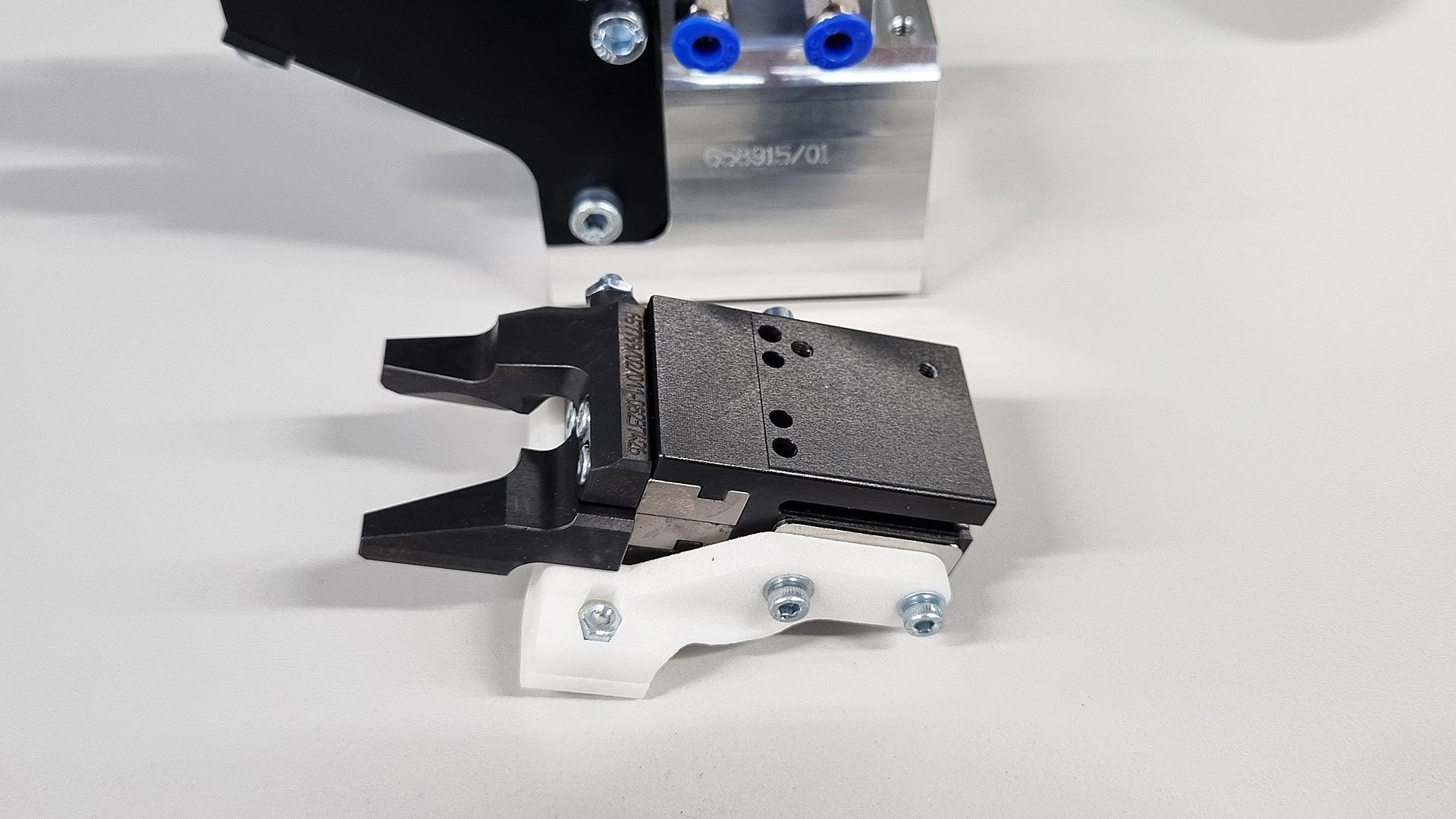

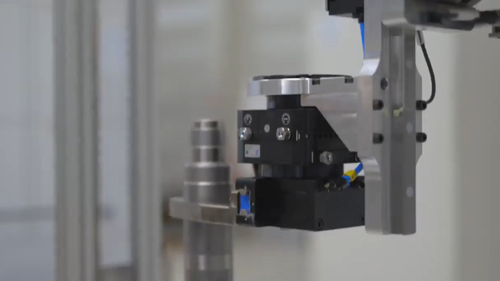

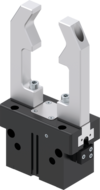

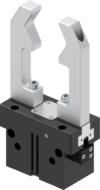

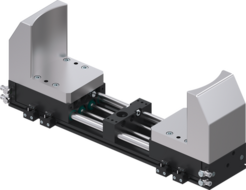

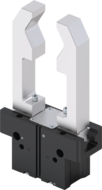

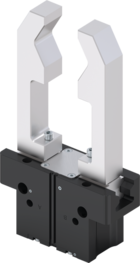

Series GPP5000AL

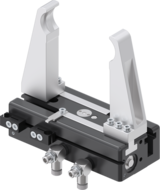

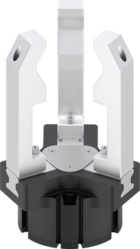

Series GPD5000AL

The money saver – Aluminum Linear Guide

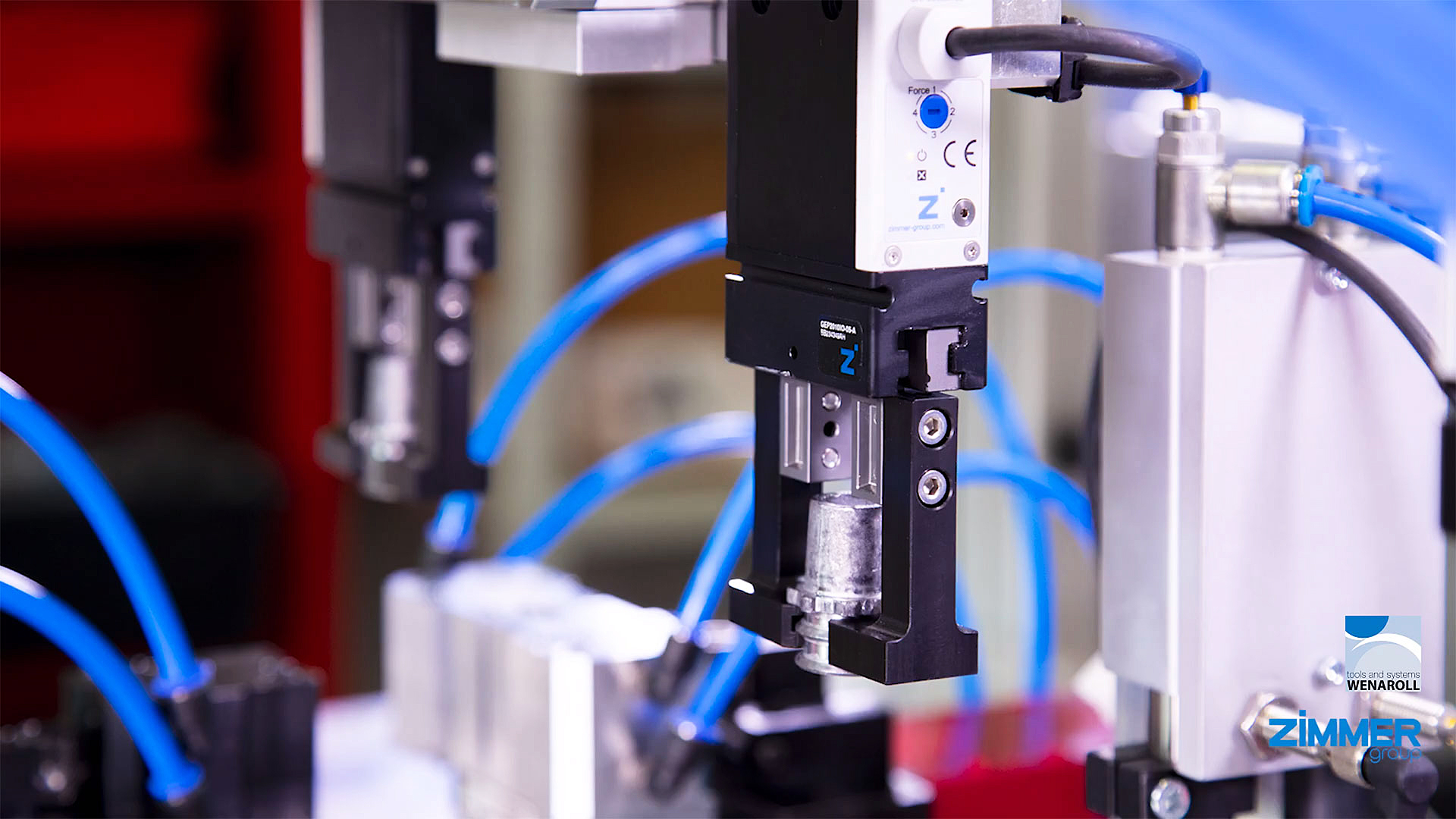

In the 5000 product family, the series equipped with Aluminum Linear Guide offer you maximum variety and flexibility at fair prices. Series GPP5000AL and GPD5000AL offer a combination of technological and economic advantages, helping you to achieve the best balance between performance and costs.

Would you like advice on the gripper series with Aluminum Linear Guide? Then write to us; we look forward to hearing from you!

Your benefits

The advantages of the series at a glance

Advantages that make the difference

Over

80%

of all applications can be covered with the economical AL version.

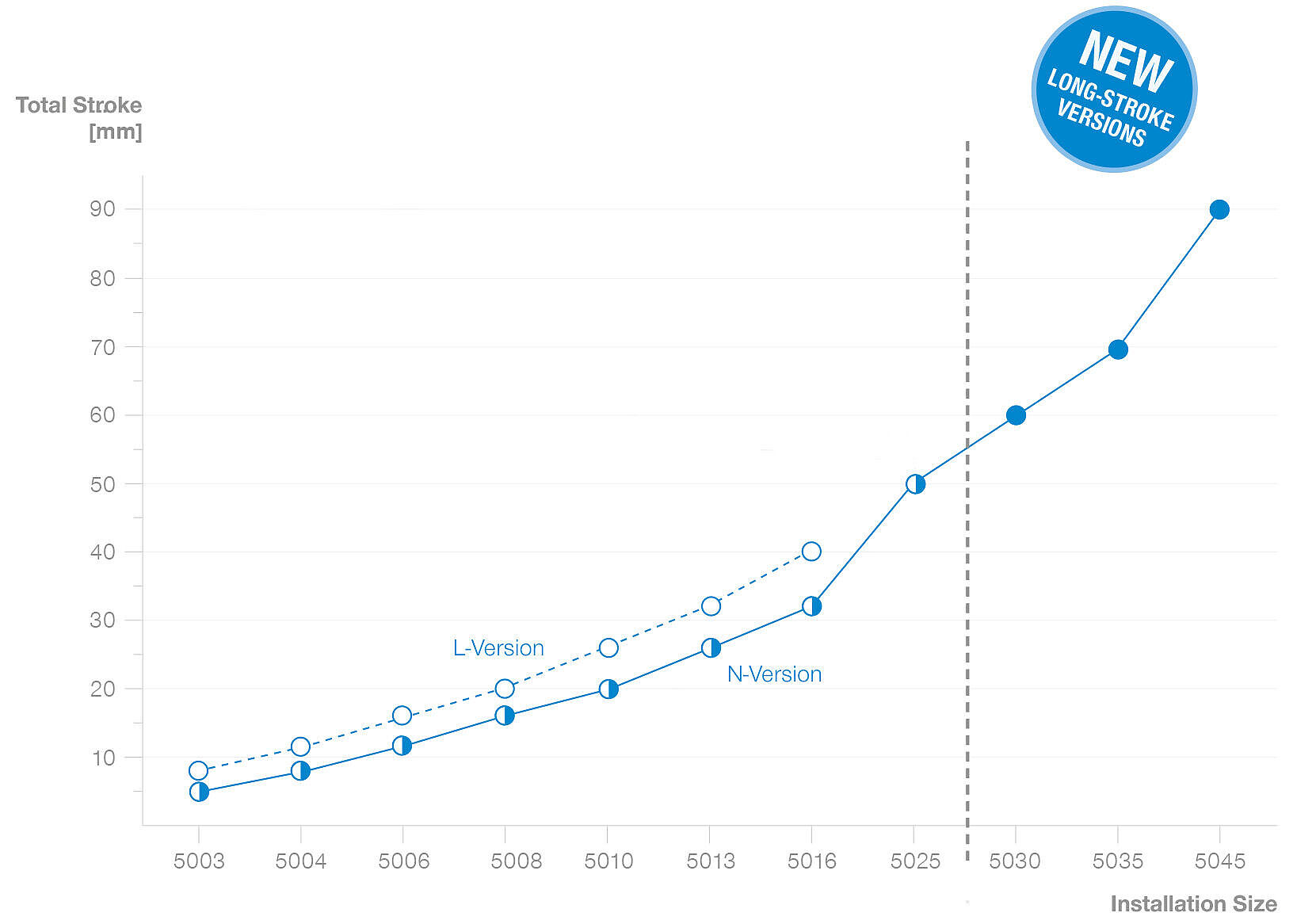

Up to

60%

more stroke for the same size with the long-stroke version.

Up to

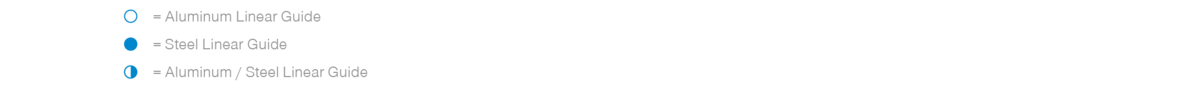

25%

price savings compared to the N variant with an identical stroke.

The market comparison

Economical and high quality

Series GPP5000AL and GPD5000AL also perform excellently in direct comparison with other grippers on the market. They have a more attractive price and their standardized mounting options and dimensions make them easy to integrate into existing designs.

Fair price-performance ratio

As a cost-effective alternative within the high-end 5000 family, the models with Aluminum Linear Guide deliver outstanding quality and reliability – ideal for price-conscious customers who do not want to compromise on the Zimmer Group quality they are accustomed to.

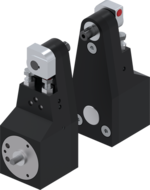

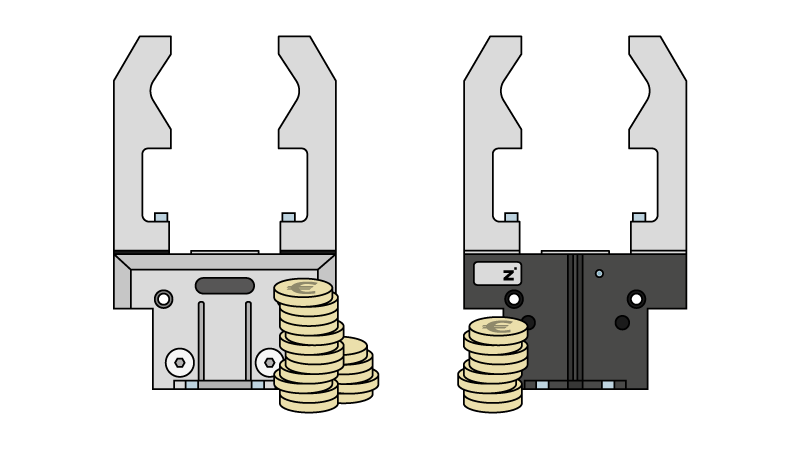

Easy changeover

The scalable 5000 product family also includes the Steel Linear Guide version (steel-in-steel), which you can switch to at any time. The standardized dimensions and interfaces, as well as the comprehensive range of accessories, ensure maximum compatibility. As a result, integration into existing systems is effortless and does not require any complex adjustments.

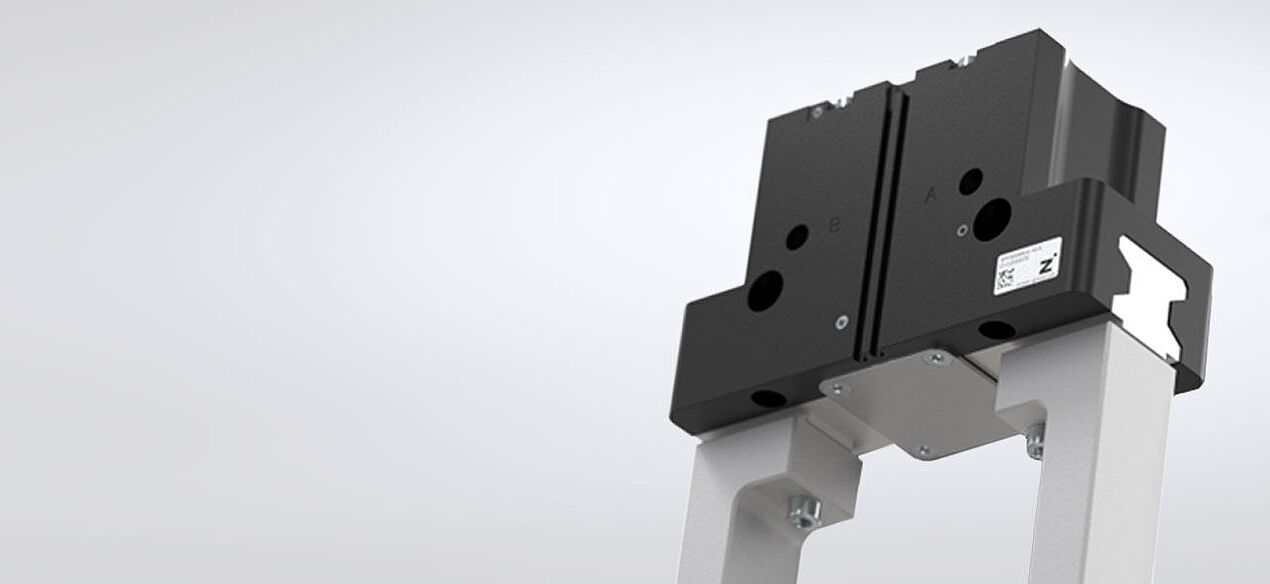

Large stroke at a small size

Thanks to the long-stroke version, you can use smaller sizes and still achieve large strokes. Your advantage: a significantly lighter and more cost-effective gripper at the same stroke. Maximum flexibility without compromising on weight, price or performance.

Our promise: Quality without compromise

Series GPP5000AL and GPD5000AL combine high precision, robustness and maximum efficiency in a unique platform concept. We are confident of our products, which is why we offer uncompromising "Made in Germany" quality for all your Series 5000 grippers. This means a full 24-month warranty – for all components and no matter how many cycles. That's a promise!

Standards and directives met

Quality and safety are fundamental elements of our corporate philosophy. Our regularly tested products not only meet the highest quality standards, but also guarantee long-term reliability and safety.

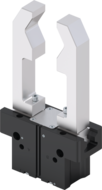

The accessories

If the operating conditions change, upgrading to Steel Linear Guide or IP-protected variants can be achieved with just a few minor adjustments – efficiently, flexibly and without a redesign. This is made possible by the wide range of accessories and installation sizes in the 5000 product family. Special features include the adjustable jaws for tool-free adjustment of the gripping range, exchangeable jaws for quick jaw changes and precise sensors that reliably monitor the entire stroke range via IO-Link or with analog signals.

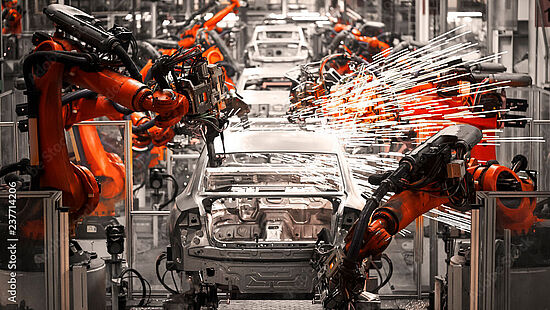

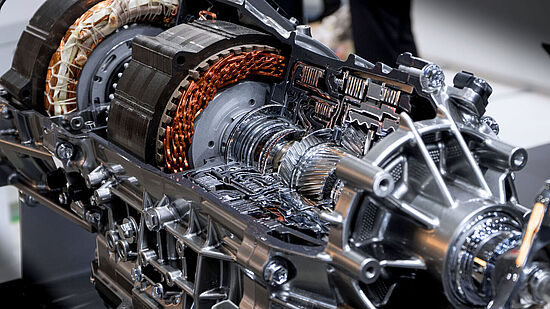

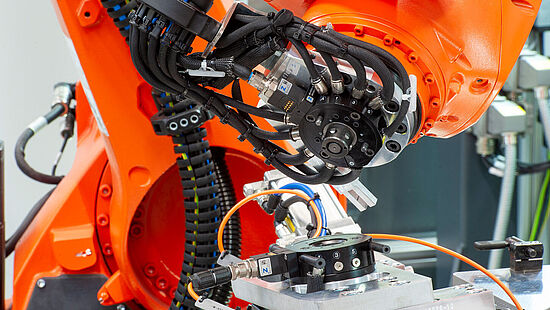

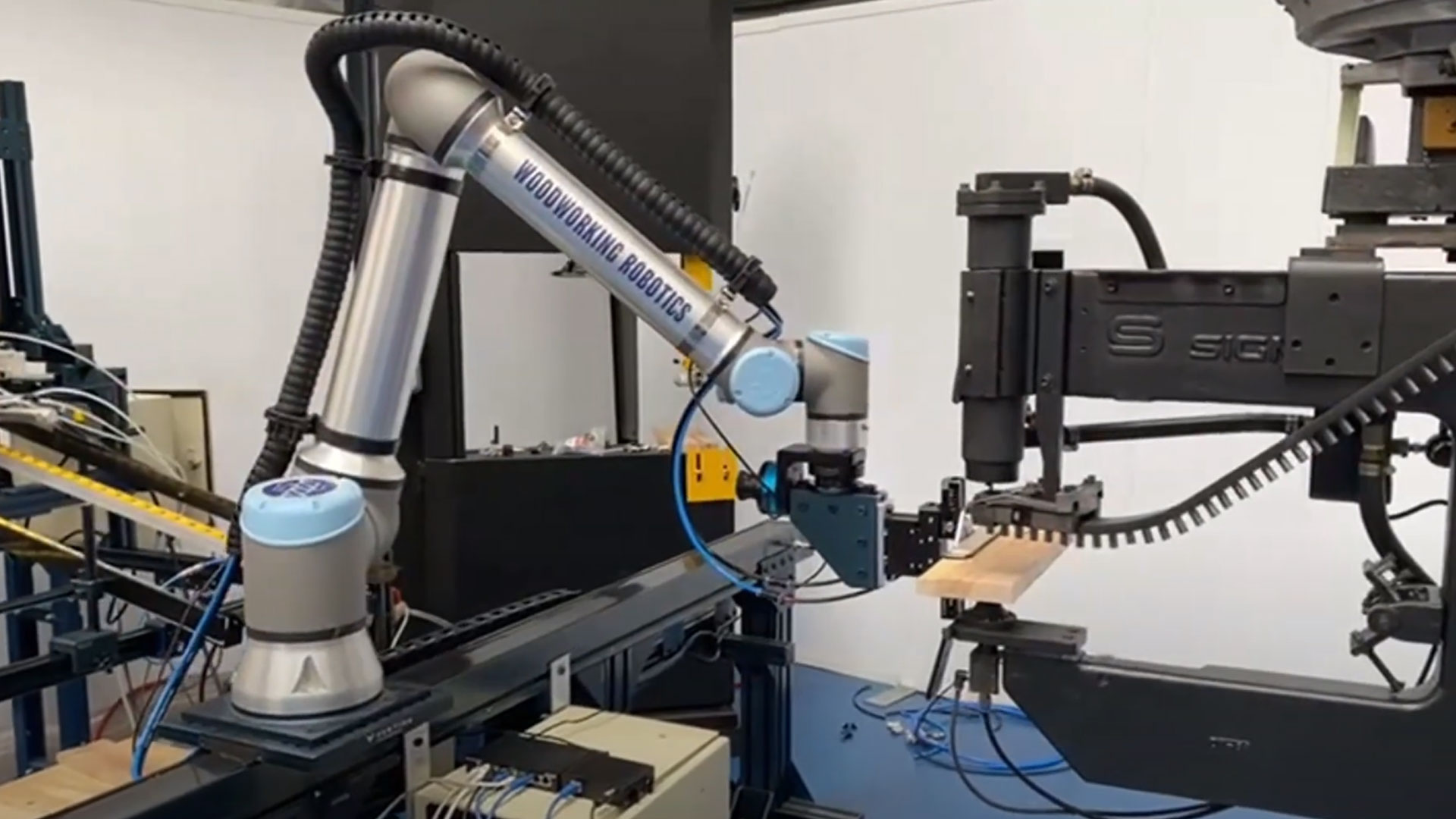

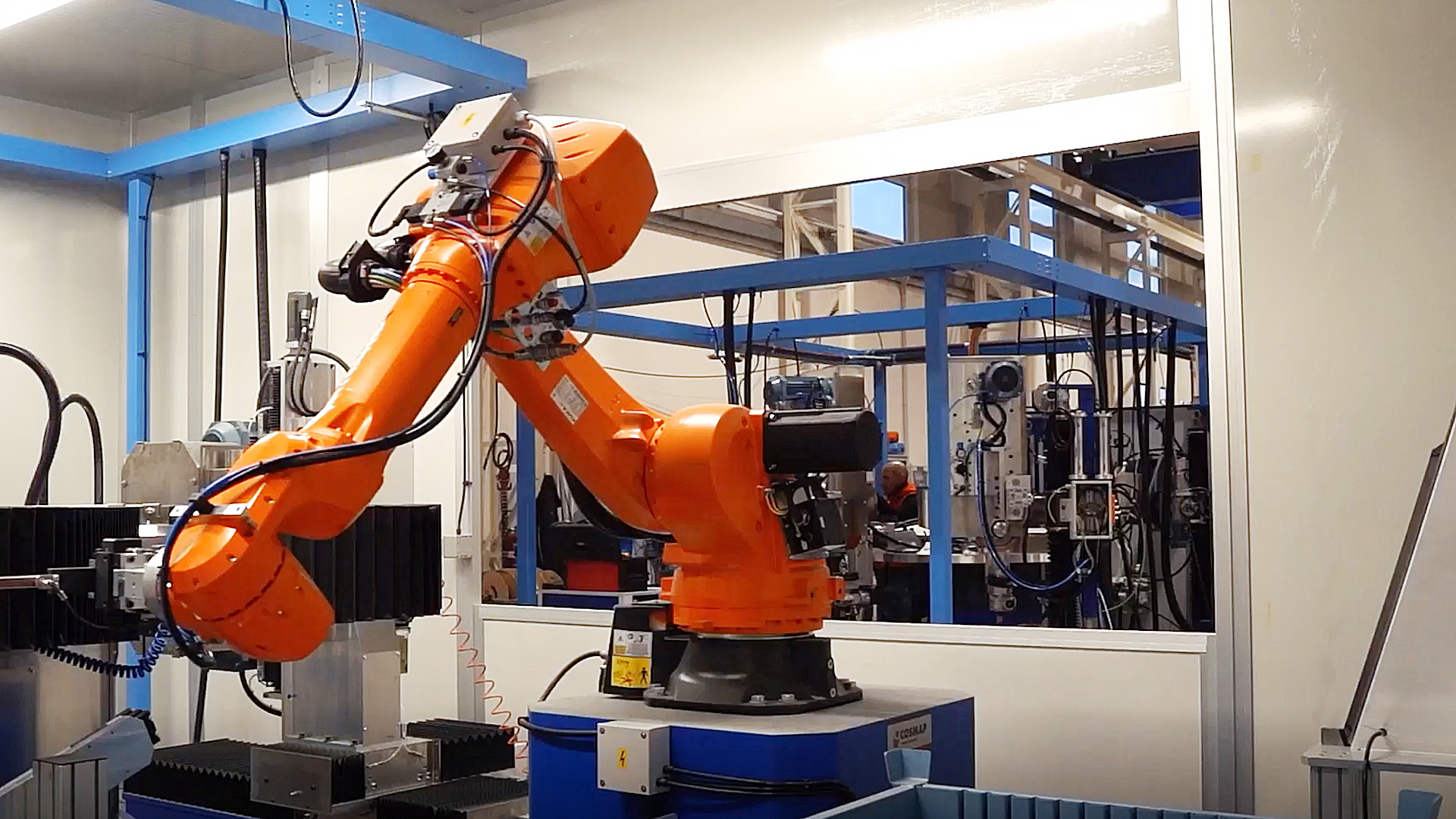

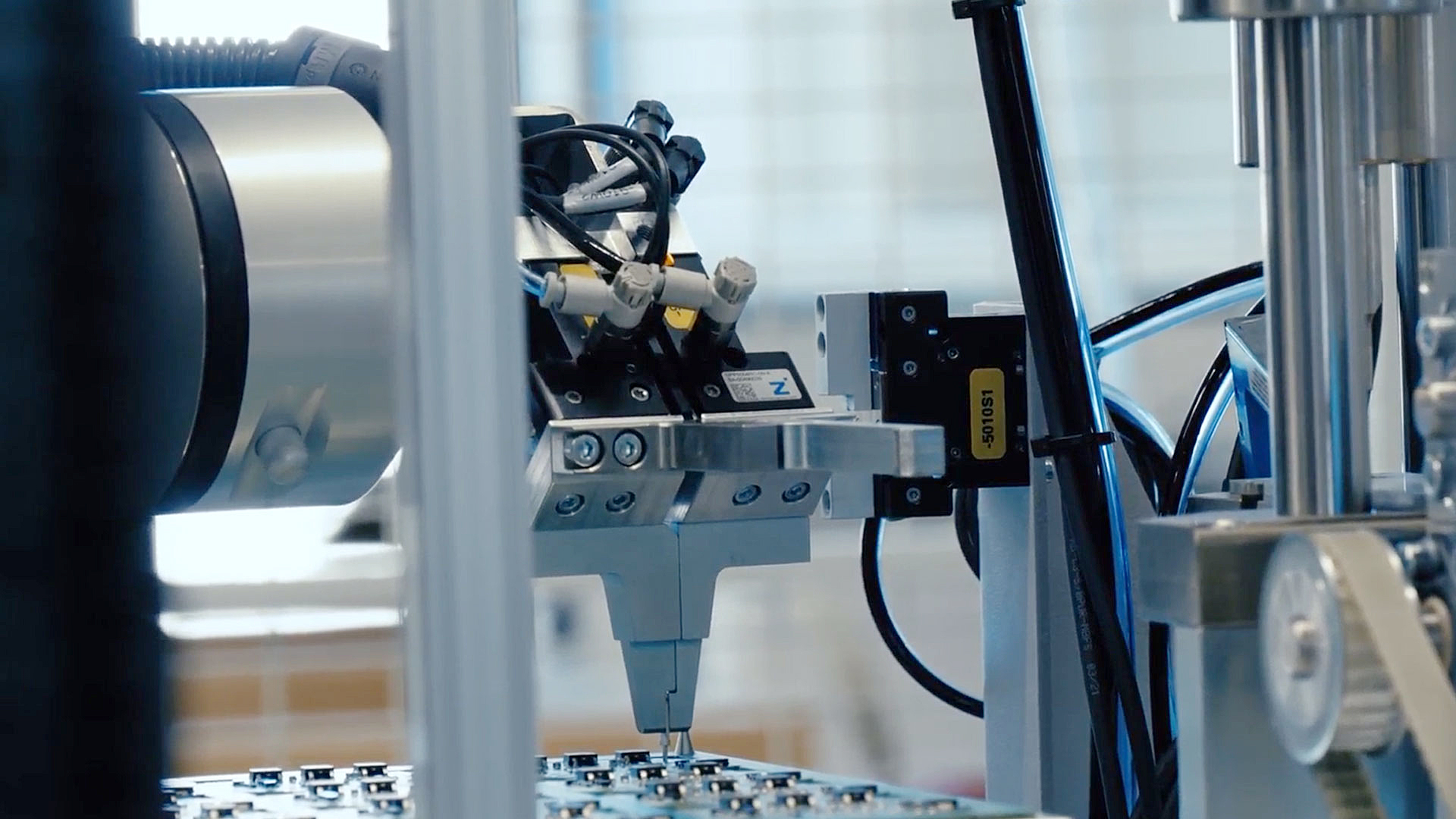

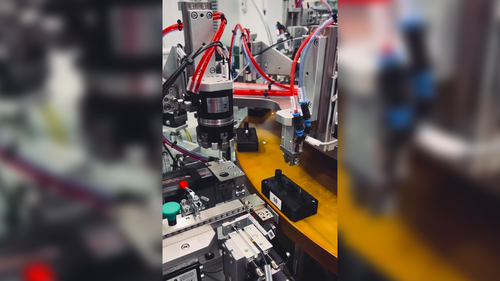

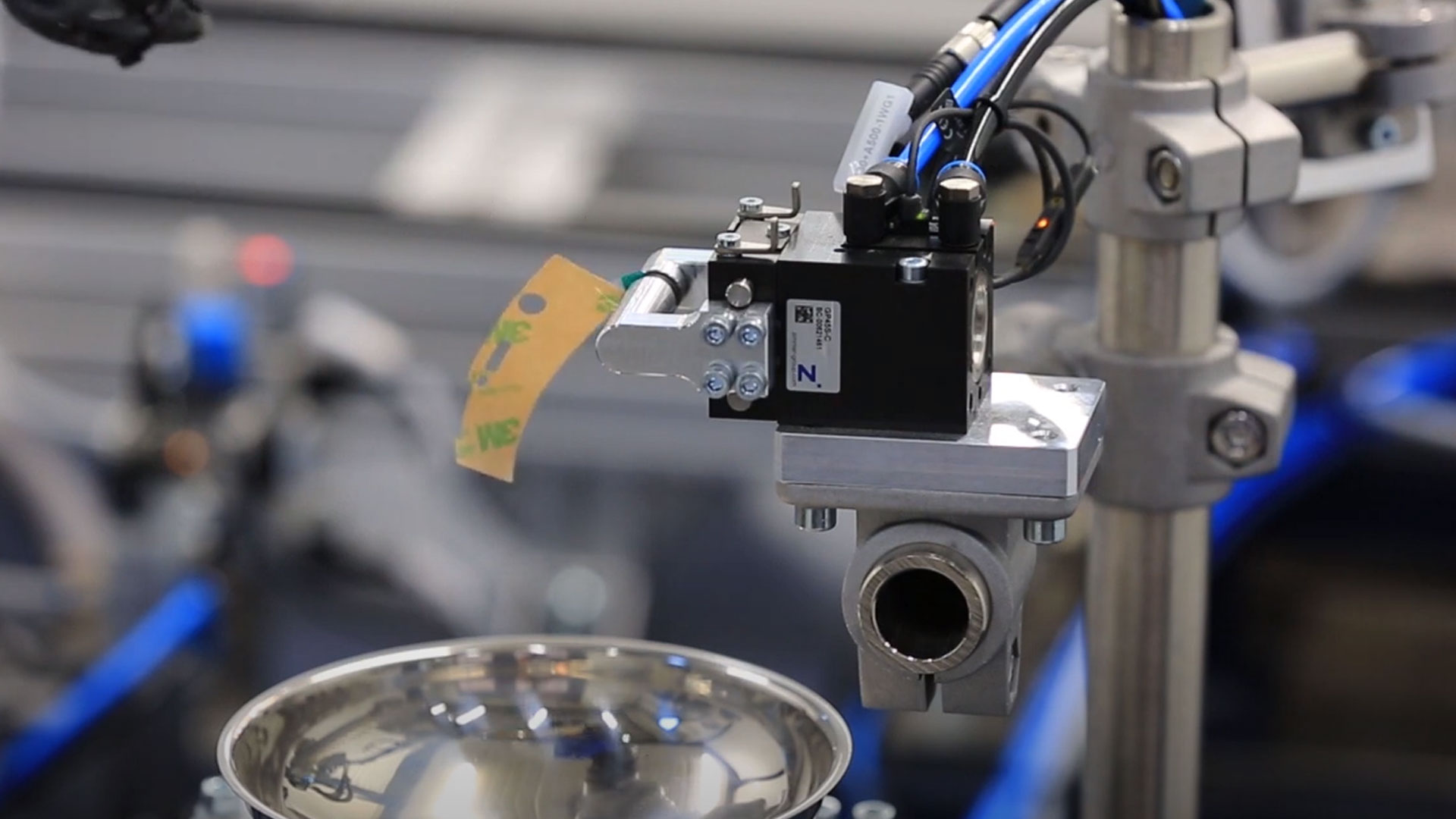

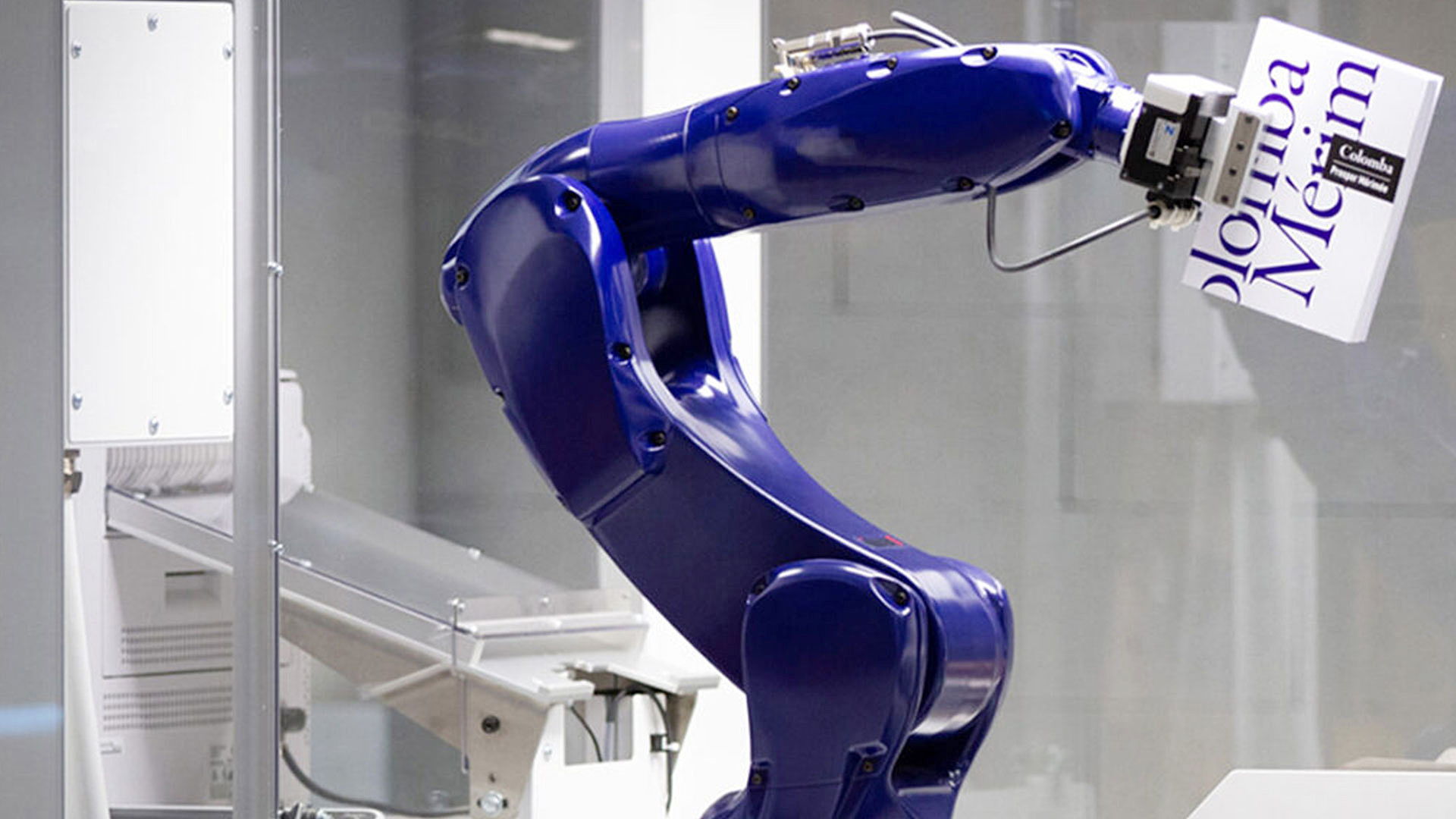

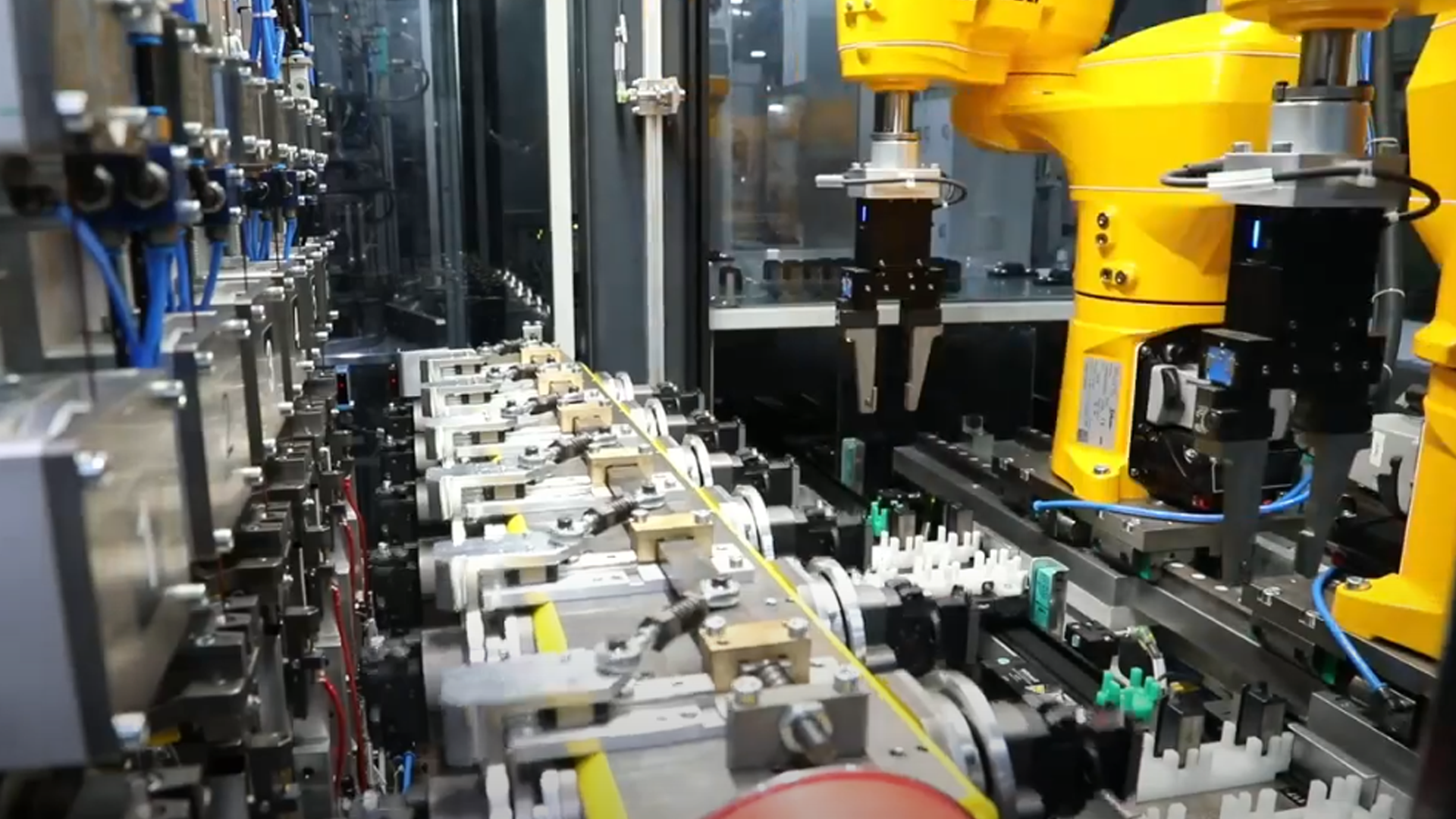

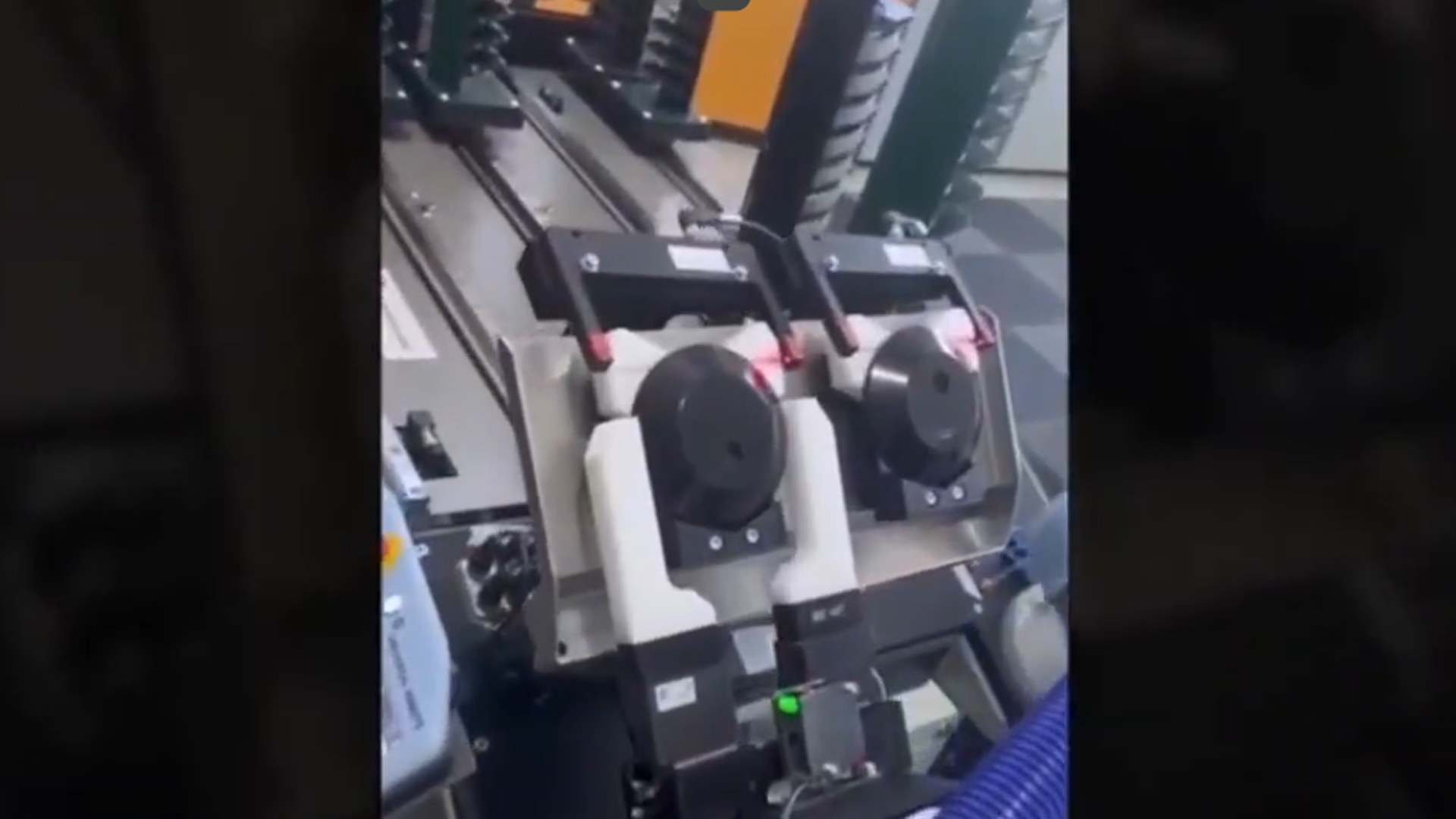

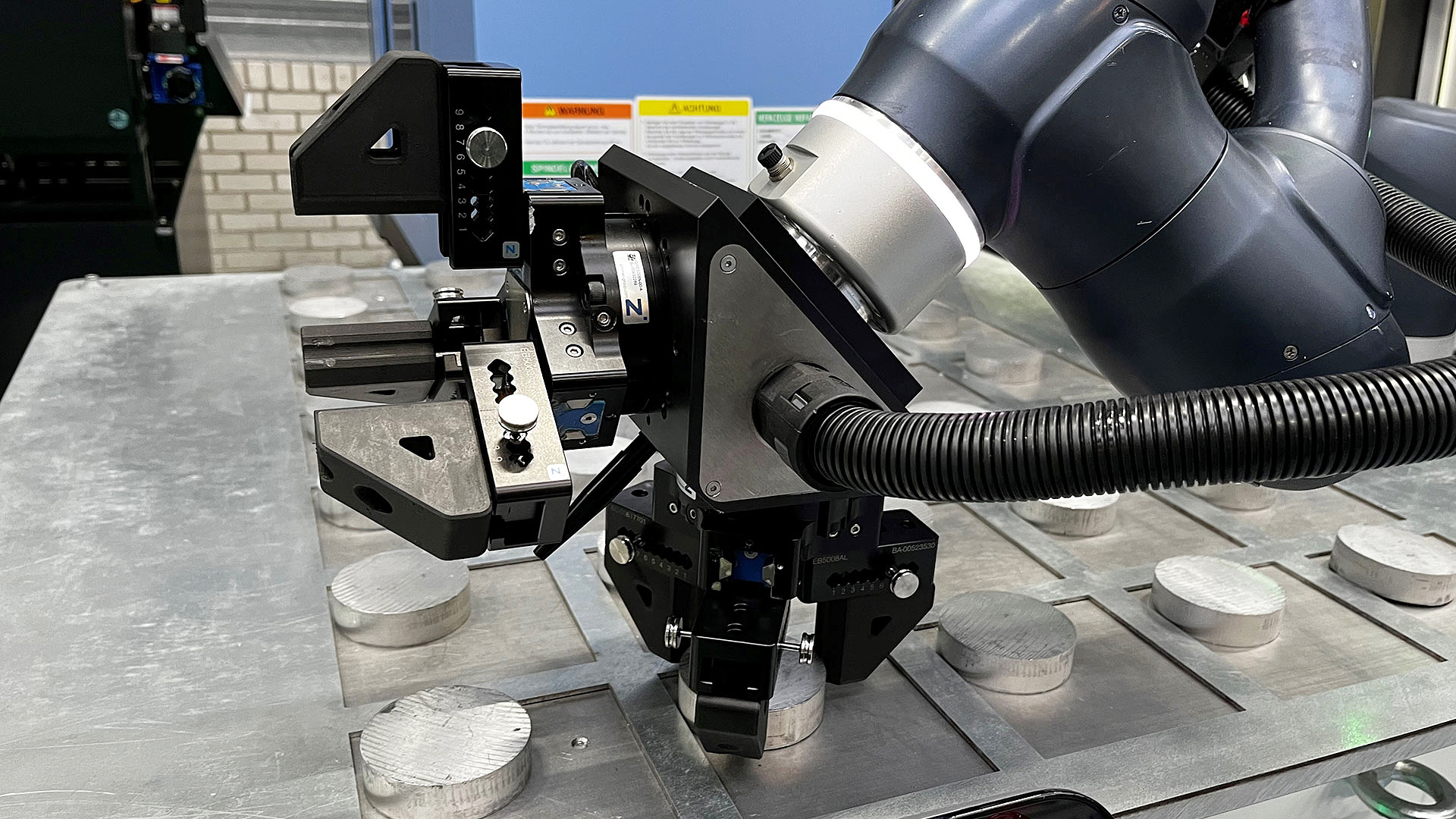

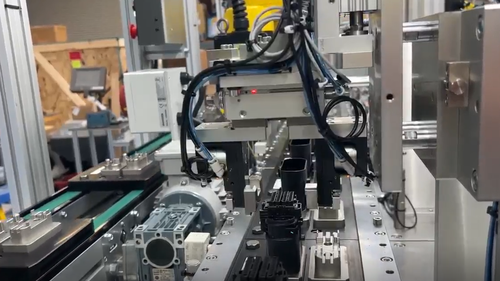

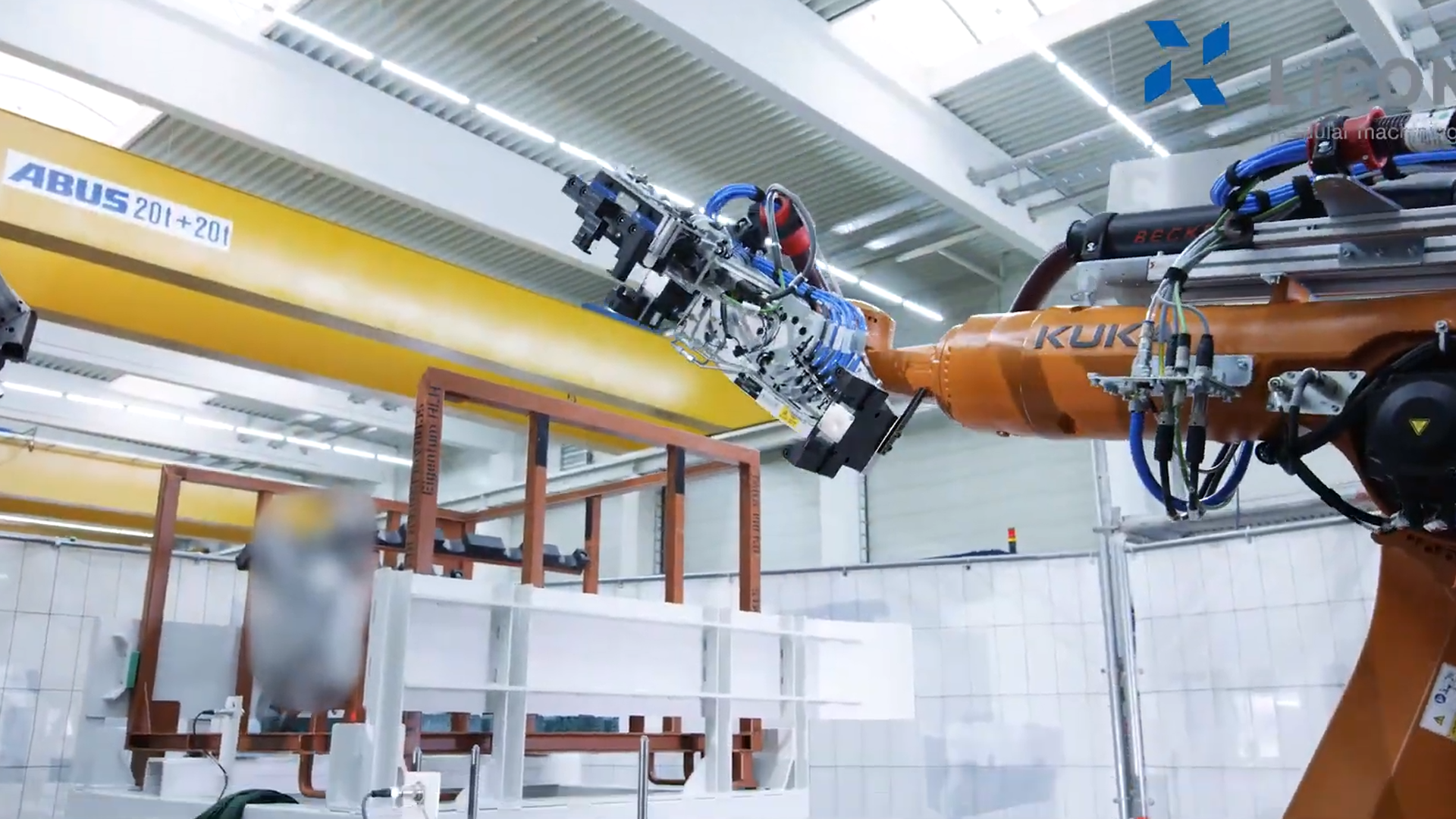

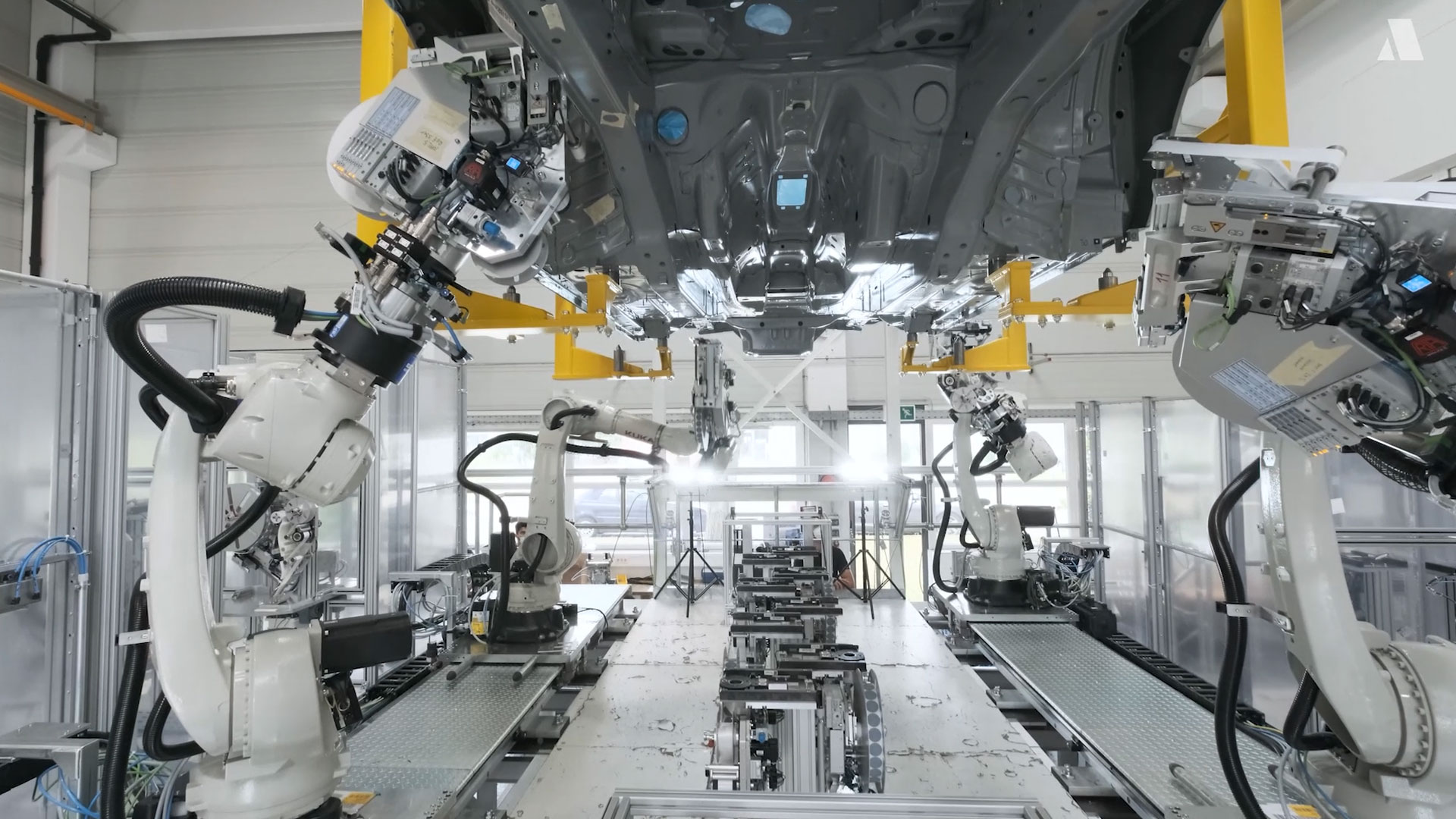

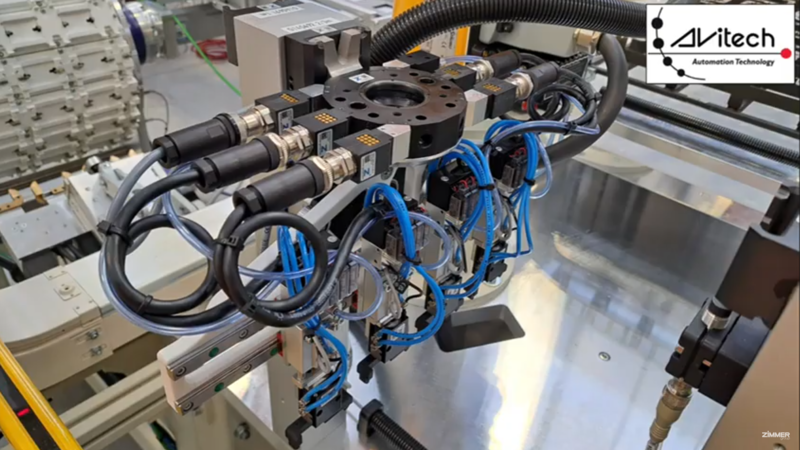

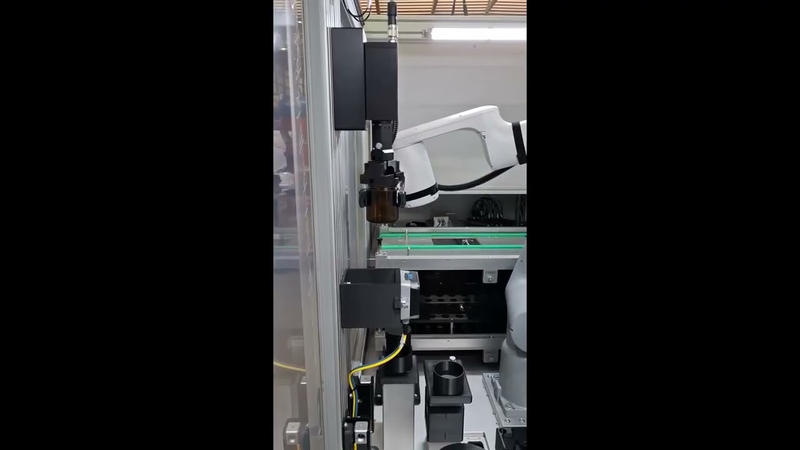

VERSATILE USE

VARIABLE FOR ALL PRODUCTION SITUATIONS

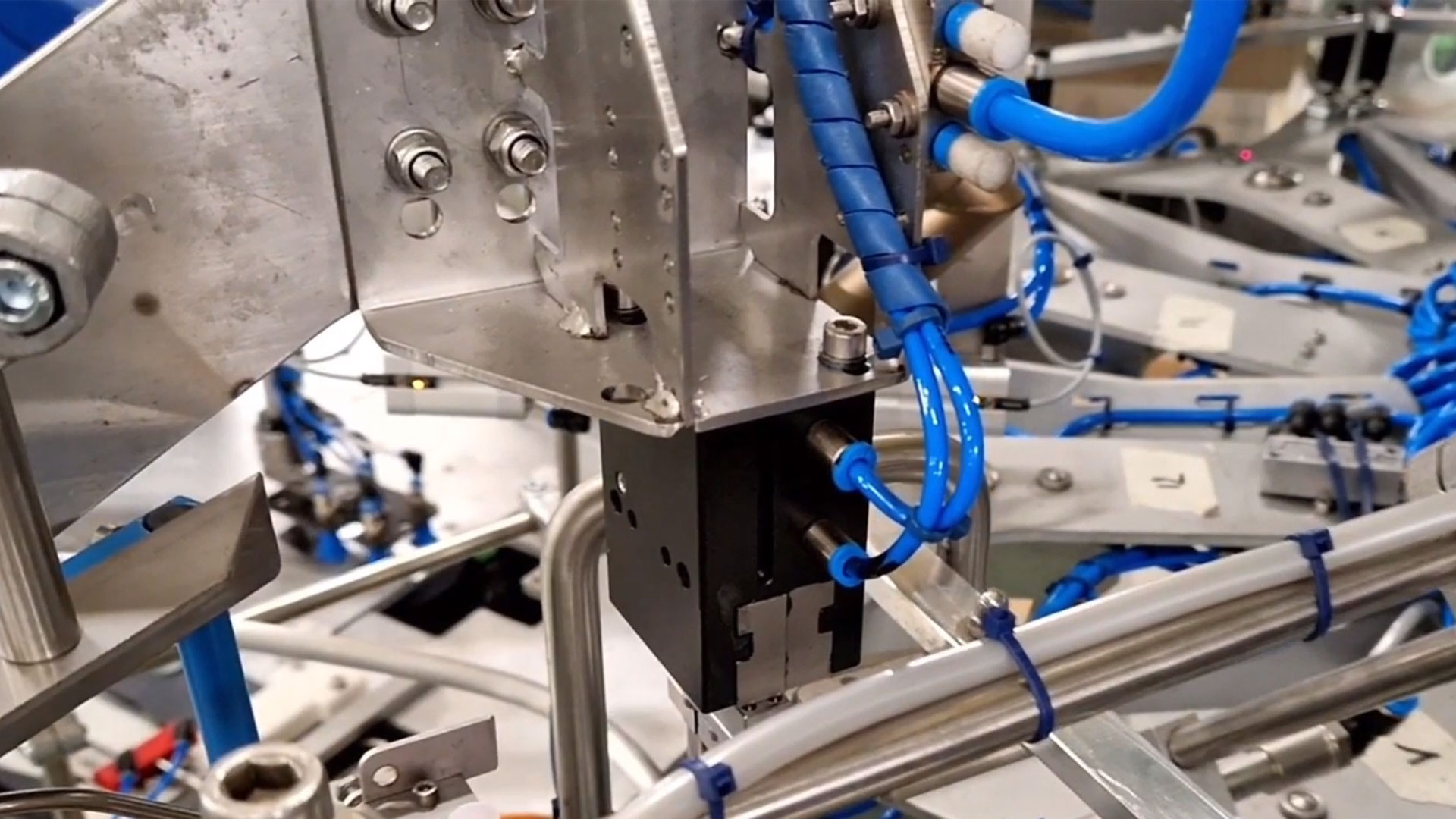

From highly automated manufacturing environments to sensitive clean room applications or flexible logistics processes – the gripper series GPP5000AL and GPD5000AL deliver impressive performance and adaptability across a wide range of industries.

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers with Long Stroke

Series GH6000

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000AL

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

3-Jaw Concentric Grippers

Series GPD5000AL

- Aluminum Linear Guide – The alternative

- Extensive accessories

- The value promise – Consistent and without fine print

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

- Aluminum Linear Guide – The alternative

- Extensive accessories

- The value promise – Consistent and without fine print

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP5000

- Approximately the same gripping force as a comparable pneumatic gripper

- Self locking mechanism in case of power drop

- Same connection hole patterns as a comparable pneumatic gripper

- Approximately the same gripping force as a comparable pneumatic gripper

- Self locking mechanism in case of power drop

- Same connection hole patterns as a comparable pneumatic gripper

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

2-Jaw Angular Rotary Grippers

Series DGK

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

Axis Compensation Modules

Series XYR1000

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK 40 ... TK 200

- Axis compensation in the X-Y plane

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK 40 ... TK 200

- Axis compensation in the X-Y plane

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

O-ring assembly grippers, outer

Series GS

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

2-Jaw Parallel Grippers

Series GP

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

- Dual round guide rods

- Double acting pneumatic cylinder with integrated mechanical gripping force safety device

2-Jaw Parallel Grippers with Long Stroke

Series GEH6000IL

2-Jaw Parallel Grippers

Series GPP5000IL

- Pneumatic drive combined with IO-Link technology

- Up to 50% cycle time reduction and up to 90% compressed air savings

- Connection via just one pneumatic line and IO-Link cable

- Pneumatic drive combined with IO-Link technology

- Up to 50% cycle time reduction and up to 90% compressed air savings

- Connection via just one pneumatic line and IO-Link cable

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Angle flange

Series WFR

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Needle gripper

Series ST

- Adjustable stroke via scale ring from 0 to 2 mm or 1.5 mm

- Single-acting pneumatic cylinder with spring return

- Adjustable stroke via scale ring from 0 to 2 mm or 1.5 mm

- Single-acting pneumatic cylinder with spring return

O-ring assembly grippers, outer

Series GS

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

- Expanding stroke adjustable from outside via adusting ring

- T-Slot guide for high forces and moments capacity

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- High gripping force as a result of optimal direction change of driving force into gripping force

Swivel Jaws

Series SB

2-Jaw Parallel Grippers with Long Stroke

Series GPH8000

- Extremely long and heavy gripper fingers possible

- Synchronous, asynchronous and securing the workpiece

- Dirt protection

- Extremely long and heavy gripper fingers possible

- Synchronous, asynchronous and securing the workpiece

- Dirt protection

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GPP5000AL

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Aluminum Linear Guide – The alternative

- Only here – larger stroke, reduced costs

- The value promise – Consistent and without fine print

2-Jaw Parallel Grippers

Series MGP800

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

- Integrated position sensing for compact design and to minimized the interfering contour

- Gripper jaws made of ground surfaced and hardened steel ensure precision and a long durability

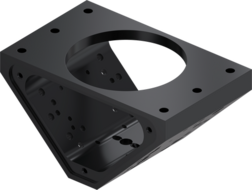

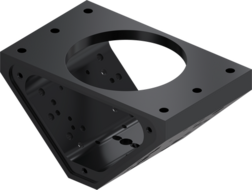

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

Tool Changers

Series WWR

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

Angle flange

Series WFR

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Return on investment

Maintenance-free and efficient

With the Aluminum Linear Guide series of the 5000 gripper family, you achieve a very fast return on your investment. The combination of low acquisition costs, maintenance-free design and maximum process reliability permanently reduces operating costs and gives you a clear competitive advantage, both technologically and economically.

Reliable even in long-term use

In the 5000 family, the series equipped with Aluminum Linear Guide are true endurance runners and stay maintenance-free for over 15 million cycles.

No downtime

High manufacturing quality ensures long-term stable operation. The grippers are reliable over millions of cycles, without unplanned downtimes or service calls.

Faster commissioning/retrofitting

Thanks to standardized dimensions and mountings, it is quick and easy to integrate the grippers into existing systems and upgrade them.

No maintenance work

The low-wear design eliminates the need for maintenance intervals. For you, this means no spare parts, no service calls, no follow-up costs.

Low investment costs

The products in Series AL make it very affordable to get started with the 5000 product family. This is where reliable performance meets affordable purchase price.

Technical data

Convincing details

| Series GPP5000AL | Technical data | ||||

|---|---|---|---|---|---|

| Installation size | Stroke per jaw [mm] | Gripping force [N] | Weight [kg] | IP class | |

| GPP5003AL | 2.5 – 4 | 85 – 205 | 0.078 – 0.093 | IP40 | |

| GPP5004AL | 4 – 6 | 130 – 295 | 0.15 – 0.19 | IP40 | |

| GPP5006AL | 6 – 8 | 230 – 485 | 0,28 – 0.34 | IP40 | |

| GPP5008AL | 8 – 10 | 390 – 750 | 0.51 – 0.61 | IP40 | |

| GPP5010AL | 10 – 13 | 650 – 1320 | 0.82 – 1 | IP40 | |

| GPP5013AL | 13 – 16 | 1115 – 1860 | 1.4 – 1.8 | IP40 | |

| GPP5016AL | 16 – 20 | 1650 – 2990 | 2.7 – 3.6 | IP40 | |

| GPP5025AL | 25 | 3280 – 4710 | 5.7 – 7.5 | IP40 | |

| Series GPD5000AL | Technical data | ||||

|---|---|---|---|---|---|

| Installation size | Stroke per jaw [mm] | Gripping force [N] | Weight [kg] | IP class | |

| GPD5003AL | 2.5 | 310 – 465 | 0.14 – 0.17 | IP40 | |

| GPD5004AL | 4 | 460 – 690 | 0.26 – 0.32 | IP40 | |

| GPD5006AL | 6 | 740 – 1080 | 0.47 – 0.57 | IP40 | |

| GPD5008AL | 8 | 1260 – 1770 | 0.88 – 1.1 | IP40 | |

| GPD5010AL | 10 | 2290 – 3250 | 1.5 – 1.9 | IP40 | |

| GPD5013AL | 13 | 3770 – 5200 | 2.8 – 3.6 | IP40 | |

| GPD5016AL | 16 | 6870 – 9490 | 6.1 – 7.7 | IP40 | |

More than just handling technology

The best service for the best grippers

With the Zimmer Group's international network, you get the benefit of direct local support worldwide. Consistent documentation and a well-designed range of accessories also ensure easy handling

and maintenance.

REPAIR SERVICE

FAQ – gripper series 5000AL (Aluminum Linear Guide)

The AL variant refers to Series 5000 grippers that have a steel/aluminum profile slot guide (Aluminum Linear Guide). This version combines proven Zimmer Group quality with a cost-optimized guide system and is ideal for price-conscious users.

The steel/aluminum guide offers:

- Better performance than classic T-slot grippers

- At least the same performance as multi-tooth guides on the market

- Attractive price-performance ratio

- Up to 15 million maintenance-free cycles

This makes the AL variant an efficient alternative for many automation tasks.

The premium grippers with Steel Linear Guide are designed for maximum robustness and precision and achieve up to 30 million maintenance-free cycles. The AL guide, on the other hand, offers lower acquisition costs and outperforms traditional T-slot guides, but has slightly different mechanical limits under extreme loads.

The performance parameters of the AL grippers include:

- Aluminum Linear Guide

- Maintenance-free service life of up to 15 million cycles

- Protection class IP40

- Protector variant available on request

- High repeat accuracy and dynamic gripping movements

The technical details vary depending on the model and installation size. Use our Product Finder or the product comparisonto make the right choice. We will also be happy to give you personal advice to find the best gripper for your application.

AL grippers are ideal:

- For clean to slightly dirty environments (clean room class 4, protection class IP40)

- For price-conscious project designs

- In standard gripping applications with moderate load requirements

- When high quality is required at a fair price-performance ratio

Series GPP5000AL and GPD5000AL cover 80% of all industrial applications. Contact us, we will help you choose the right gripper: Contact

Changing to grippers with Aluminum Linear Guide is usually quite easy. Thanks to the standardized dimensions of the structure and mounting, the GPP5000AL and GPD5000AL models can usually be integrated directly into existing systems. The extensive range of accessories is compatible with all grippers in the 5000 product family, which minimizes the amount of adjustments required. Even a later upgrade to the more robust grippers with Steel Linear Guide is possible without major adjustments. In addition, the Zimmer Group provides practical support with advice, integration, commissioning, maintenance and repair – including technical support, diagnostics, troubleshooting and original spare parts for reliable system connectivity throughout the entire life cycle.