GPW5013NC-20-A

2-Jaw Angular Grippers

Series GPW5000

"The Universal One"

- Highest performance with the smallest dimensions

Features a one-of-a-kind ratio of net mass to gripper finger length and gripping moment. The performance of your machine is increased as a result. - Versatile applicability

Thanks to standard functionality such as IP64 and corrosion protection, you are able to use these grippers in almost any of your applications. Even the toughest environments are no problem. - Robust and process-reliable

Thanks to a maintenance-free design up to 30 million cycles and the most solid force transmission possible, process assurance is maximized.

Equipment/Options

30 million maintenance-free cycles (max.)

30 million maintenance-free cycles (max.) Spring closing C

Spring closing C IP64

IP64 Protected against corrosion

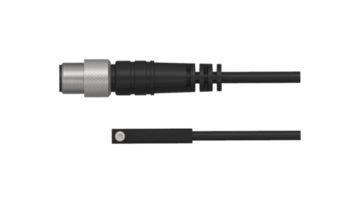

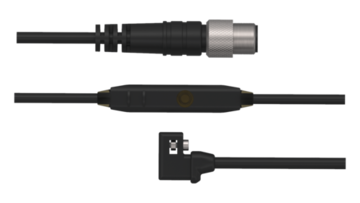

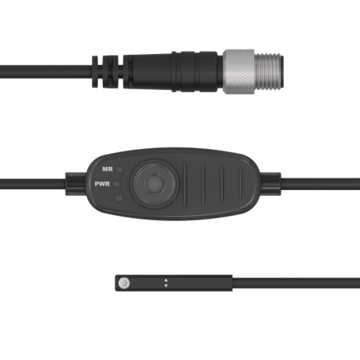

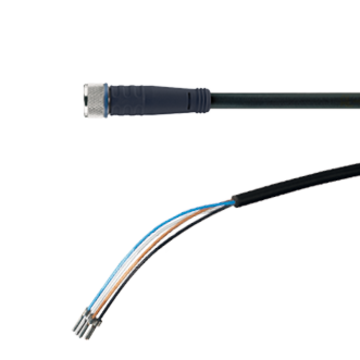

Protected against corrosion Magnetic field sensor

Magnetic field sensor Inductive sensor

Inductive sensor Purged air

Purged air Temperature-resistant

Temperature-resistant

Technical Data

| Stroke per jaw (+/-) | +15/-2 [°] |

| Gripping moment in closing max. | 130 [Nm] |

| Gripping moment secured by spring min. | 39.5 [Nm] |

| Gripping force in closing at 0° | 4200 [N] |

| Closing time | 0.08 [s] |

| Opening time | 0.12 [s] |

| Dead weight of mounted gripper finger max. | 2.4 [kg] |

| Length of the gripper fingers max. | 185 [mm] |

| Repetition accuracy +/- | 0.01 [mm] |

| Operating pressure | 4 ... 8 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | -10 ... +130 [°C] |

| Air volume per cycle | 160 [cm³] |

| Approvals | LABS / REACH / RoHS |

| Protection to IEC 60529 | IP64 |

| Weight | 3 [kg] |

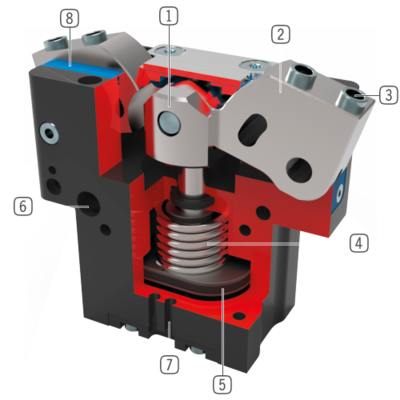

Benefits in detail

- Positively driven lever mechanism

synchronized the movement of the gripper jaws - Gripper jaw

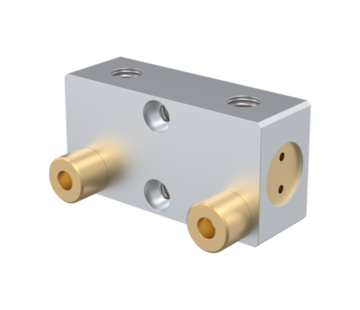

Gripper fingers mounted using removable centering sleeves - Removable centering sleeves

quick and economical positioning of the gripper fingers - Integrated gripping force safety device

Spring built into cylinder chamber as an energy store - Drive

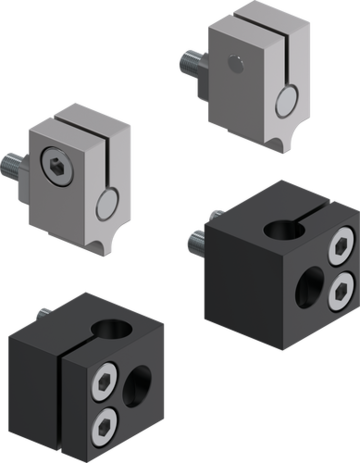

Double-acting pneumatic rotor cylinder - Mounting and positioning

Alternatively, on several sides for customized mounting - Sensing slot

mounting and positioning of magnetic field sensors - Dual lip seal

IP64 Prevents grease from being squeezed out, increasing service life