GPP5013SC-IL-10-A

2-Jaw Parallel Grippers

Series GPP5000IL

"The hybrid"

- Pneumatic drive combined with IO-Link technology

- Up to 50% reduction in cycle times and up to 90% less compressed air usage

- Connection over just one pneumatic line and IO-Link cable

- Integrated valve technology, sensor technology, status display, pressure monitoring and temperature monitoring

- Part detection down to +/- 0.05 mm for a tolerance range that can be taught for any value

- 32 workpieces data sets can be programmed

- Protected from corrosion and sealed in accordance with IP64

- Up to 30 million cycles without maintenance

Equipment/Options

30 million maintenance-free cycles (max.)

30 million maintenance-free cycles (max.) Spring closing C

Spring closing C High-strength S

High-strength S Integrated sensing

Integrated sensing IP64

IP64 Protected against corrosion

Protected against corrosion Purged air

Purged air IO-Link

IO-Link Integrated valve technology

Integrated valve technology

Technical Data

| Control | IO-Link |

| Stroke per jaw | 6 [mm] |

| Gripping force in closing | 4220 [N] |

| Gripping force secured by spring min. | 1120 [N] |

| Cycle count max. | 220 [cycle/min] |

| Dead weight of mounted gripper finger max. | 2.4 [kg] |

| Length of the gripper fingers max. | 170 [mm] |

| Repetition accuracy +/- | 0.01 [mm] |

| Operating pressure | 4 ... 7 [bar] |

| Nominal operating pressure | 6 [bar] |

| Operating temperature | +5 ... +50 [°C] |

| Air volume per cycle | 171 [cm³] |

| Integrated valve technology | Yes |

| Integrated position sensing | Yes |

| Voltage | 24 [V] |

| Current consumption max. | 0.12 [A] |

| Certifications | CE / UKCA / LABS / REACH / RoHS |

| Protection to IEC 60529 | IP64 |

| Weight | 3 [kg] |

Benefits in detail

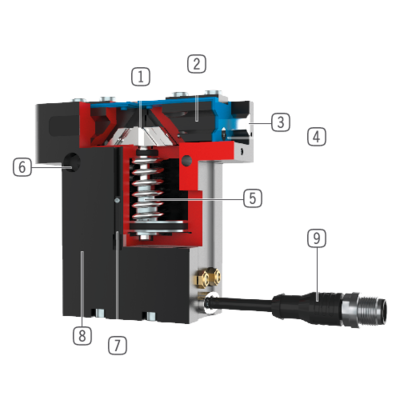

- Wedge hook mechanism

Supports to absorb high forces and moments Synchronized gripper jaw movement - Gripper jaw

Gripper fingers mounted using removable centering sleeves Lubricated for life via incorporated lubrication slots - Steel Linear Guide

Steel in steel guide Enables use of extremely long gripper fingers - Dual lip seal

IP64 Prevents grease from being squeezed out, increasing service life - Integrated gripping force safety device

Spring built into cylinder chamber as an energy store - Mounting and positioning

Alternatively, on several sides for customized mounting - Position sensing

integrated Hallsensor - Integrated valve technology

Activation of the gripper by means of a compressed air supply - Integrated control module

Single-cable solution via IO-Link Pressure, temperature, position and other parameters are readable