WWR125F-B

Vorgängermodell

Hinweis zum Vorgängermodell

Dieses Produkt gehört zu unseren Vorgängermodellen und ist weiterhin hier zu finden, um Ihnen technische Informationen und Support bereitzustellen. Falls Sie Fragen zu diesem Vorgängermodell haben, nutzen Sie bitte das Kontaktformular – wir helfen Ihnen gerne weiter!

Für Produktanfragen nutzen Sie bitte den Link oben zum weiterentwickelten Nachfolgemodell.

Werkzeugwechsler

Serie WWR

Technische Daten

| Anschlussflansch nach EN ISO 9409-1 | TK 125 |

| Energieübertragung pneumatisch | 10 [Anzahl] |

| Durchfluss je Überträger | 500 [l/min] |

| Energieübertragung elektrisch | optional |

| Energieübertragung hydraulisch | optional |

| Selbsthemmung beim Verriegeln | mechanisch |

| Verriegelungshub | 1.3 [mm] |

| Wiederholgenauigkeit in Z | 0.01 [mm] |

| Wiederholgenauigkeit in X, Y | 0,02 [mm] |

| Fügekraft | 150 [N] |

| Lösekraft | 80 [N] |

| Achsversatz beim Koppeln max. in X, Y | 2.85 [mm] |

| Betriebsdruck | 4 ... 10 [bar] |

| Nennbetriebsdruck | 6 [bar] |

| Betriebstemperatur | 5 ... +80 [°C] |

| Zylindervolumen pro Zyklus | 80 [cm³] |

| Massenträgheitsmoment | 48 [kgcm²] |

| Gewicht | 2.2 [kg] |

| Empfohlenes Handlingsgewicht | 230 [kg] |

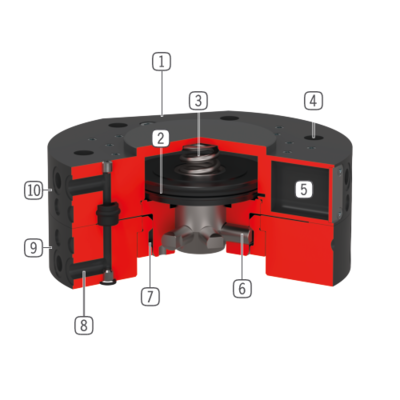

Aufbau im Schnitt

- Befestigung Energieelement

- Antrieb

doppeltwirkender Pneumatikzylinder - Integrierte Feder

Energiespeicher bei Druckabfall - Roboterflansch

Teilkreis nach EN ISO 9409-1 - Kolbenstellungsabfrage

über Magnetfeldsensor - Verriegelungsbolzen

der Verriegelungshülse angepasst - Verriegelungshülse

hohe Momentenaufnahme - Integrierte Luftdurchführung

Luft- / Vakuumdurchführung Schlauchlose Ansteuerung möglich - Losteil

Zur werkzeugseitigen Montage - Festteil

Zur roboterseitigen Montage

Energieelemente

Übertragungsart Kommunikation

| Anschlussgewinde | Anzahl Fluidkupplungen | Anzahl Kontakte | ||

|---|---|---|---|---|

| WER3000FIL01-00 |  | M12 | 5 | |

| WER3000FIL01-09-A |  | M12 | 5 | |

| WER3000FPB01-00 |  | M12 | 5 | |

| WER3000FPN01-00 |  | M12 | 4 | |

| WER3000FPN01-09-A |  | M12 | 4 | |

| WER3000FIL01-18-A |  | M12 | 4 |

Übertragungsart elektrisch

| Anschlussgewinde | Anzahl Fluidkupplungen | Anzahl Kontakte | ||

|---|---|---|---|---|

| WER3000FLA01-00-A |  | M8 | 1 | |

| WER3000FLA06-00 |  | M23 | 5+PE | |

| WER3000FLA08-00 |  | M23 | (3+PE) / 4 | |

| WER3000FSI11-20-A |  | M23 | 11+1 | |

| WER3000FSI11-21-A |  | M23 | 11+1 | |

| WER3000FSI12-00 |  | M23 | 12 | |

| WER3000FSI12-09-A |  | M23 | 12 | |

| WER3000FSI14-01-A |  | M23 | 14+5 Sensorik | |

| WER3000FSI14-02-A |  | M23 | 14+5 Sensorik | |

| WER3000FSI14-16-A |  | M23 | 14+5 Sensorik | |

| WER3000FSI14-17-A |  | M23 | 14+5 Sensorik | |

| WER3000FSI18-20-A |  | M23 | 18+1 | |

| WER3000FSI18-21-A |  | M23 | 18+1 | |

| WER3000FSI19-00 |  | M23 | 19 | |

| WER3000FSI19-09-A |  | M23 | 19 | |

| WER3000FSI08-18-A |  | M12 | 8+2 | |

| WER3000FLA01-27-A |  | 1 |

Übertragungsart fluidisch

| Anschlussgewinde | Anzahl Fluidkupplungen | Anzahl Kontakte | ||

|---|---|---|---|---|

| WER3000FFL01-03-A |  | G1/4" | 1 |

Übertragungsart pneumatisch

| Anschlussgewinde | Anzahl Fluidkupplungen | Anzahl Kontakte | ||

|---|---|---|---|---|

| WER3000FPL01-04 |  | G3/8" | 1 | |

| WER3000FPL02-03 |  | G1/4" | 2 | |

| WER3000FPL04-06-A |  | G1/8" | 4 |